Choke (electronics)

Sep 08, 2018|

Sep 08, 2018| View:1193

View:1193

Choke (electronics)

From Wikipedia, the free encyclopediaFor other uses, see Choke (disambiguation). A choke, with two 20 mH windings and rated to handle 2 A

A choke, with two 20 mH windings and rated to handle 2 A

In electronics, a choke is an inductor used to block higher-frequency alternating current (AC) in an electrical circuit, while passing lower-frequency or direct current (DC). A choke usually consists of a coil of insulated wire often wound on amagnetic core, although some consist of a doughnut-shaped "bead" of ferrite material strung on a wire. The choke's impedanceincreases with frequency. Its low electrical resistance passes both AC and DC with little power loss, but its reactancelimits the amount of AC passed.

The name comes from blocking—"choking"—high frequencies while passing low frequencies. It is a functional name; the name "choke" is used if an inductor is used for blocking or decoupling higher frequencies, but is simply called an "inductor" if used in electronic filters or tuned circuits. Inductors designed for use as chokes are usually distinguished by not having the low-loss construction (high Q factor) required in inductors used in tuned circuits and filtering applications.

Contents

Types and construction[edit]

An MF or HF radio choke for tenths of an ampere, and a ferrite bead VHF choke for several amperes.

An MF or HF radio choke for tenths of an ampere, and a ferrite bead VHF choke for several amperes. A ferrite "bead" choke, consisting of a cylinder of ferrite encircling a computer power cord to block electronic noise.

A ferrite "bead" choke, consisting of a cylinder of ferrite encircling a computer power cord to block electronic noise.

Chokes are divided into two broad classes:

Audio frequency chokes (AFC) – designed to block audio and power line frequencies while allowing DC to pass

Radio frequency chokes (RFC) – designed to block radio frequencies while allowing audio and DC to pass.

Audio frequency chokes[edit]

Audio frequency chokes (AFC) usually have ferromagnetic cores to increase their inductance. They are often constructed similarly to transformers, with laminated iron cores and an air gap. The iron core helps to improve inductance.[1] A major use in the past was in power rectifiers and direct current motor controllers to produce direct current (DC), where they were used in conjunction with large electrolytic capacitors to remove the voltage ripple (AC) at the output DC. A rectifier circuit designed for a choke-output filter may produce too much DC output voltage and subject the rectifier and filter capacitors to excessive in-rush and ripple currents if the inductor is removed. However, modern electrolytic capacitors with high ripple current ratings, and voltage regulators that remove more power supply ripple than chokes could, have eliminated heavy, bulky chokes from mains frequency power supplies. Smaller chokes are used in switching power supplies to remove the higher-frequency switching transients from the output and sometimes from feeding back into the mains input. They often have toroidal ferrite cores.

Some DIY car audio hobbyists use choke coils with car audio systems (specifically in the wiring for a subwoofer, to remove high frequencies from the amplified signal).

Radio frequency chokes[edit]

Radio frequency chokes (RFC) often have iron powder or ferrite cores which increases inductance and overall operation.[1]They are often wound in complex patterns (basket winding) to reduce self-capacitance and proximity effect losses. Chokes for even higher frequencies have non-magnetic cores and low inductance.

A modern form of choke used for eliminating digital RF noise from lines is the ferrite bead, a cylindrical or torus-shaped core of ferrite slipped over a wire. These are often seen on computer cables. A typical RF choke value could be 2 millihenries.

Common-mode (CM) chokes[edit]

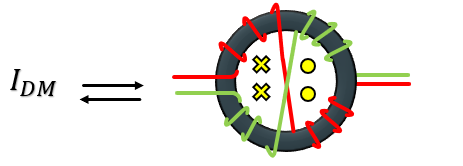

A typical common-mode choke configuration. The common mode currents, I1 and I2, flowing in the same direction through each of the choke windings, creates equal and in-phase magnetic fields which add together. This results in the choke presenting a high impedance to the common mode signal.[2]

A typical common-mode choke configuration. The common mode currents, I1 and I2, flowing in the same direction through each of the choke windings, creates equal and in-phase magnetic fields which add together. This results in the choke presenting a high impedance to the common mode signal.[2]

The common-mode choke, where two coils are wound on a single core, is useful for suppression ofelectromagnetic interference (EMI) and radio frequency interference (RFI) from power supply lines and for prevention of malfunctioning of power electronics device. It passes differential currents (equal but opposite), while blocking common-mode currents.[3] The magnetic flux produced by differential-mode (DM) currents in the core tend to cancel each other out since the windings are negative coupled. Thus, the choke presents little inductance or impedance to DM currents. Normally this also means that the core will not saturate for large DM currents and the maximum current rating is instead determined by the heating effect of the winding resistance. The CM currents, however, see a high impedance because of the combined inductance of the positive coupled windings.

CM chokes are commonly used in industrial, electrical and telecommunications applications to remove or decrease noise and related electromagnetic interference.[4]

Near magnetic field emission reduction[edit]

When the CM choke is conducting CM current, most of the magnetic flux generated by the windings is confined with the inductor core because of its high permeability. In this case, the leakage flux, which is also the near magnetic field emission of the CM choke is low. However, the DM current flowing through the windings will generate high emitted near magnetic field since the windings are negative coupled in this case. To reduce the near magnetic field emission, a twisted winding structure can be applied to the CM choke.

A balanced twisted windings CM choke

A balanced twisted windings CM choke The prototype of the balanced twisted winding CM choke

The prototype of the balanced twisted winding CM choke

The difference between the balanced twisted windings CM choke and conventional balanced two winding CM choke is that the windings interact in the center of the core open window. When it is conducting CM current, the balanced twisted winding CM inductor can provide identical CM inductance as the conventional CM inductor. When it is conducting DM current, the equivalent current loops will generate inversed direction magnetic fields in space so that they tend to cancel each other.

The equivalent current loops and the magnetic fields generated

The equivalent current loops and the magnetic fields generated

Measurement for near magnetic field emission[edit]

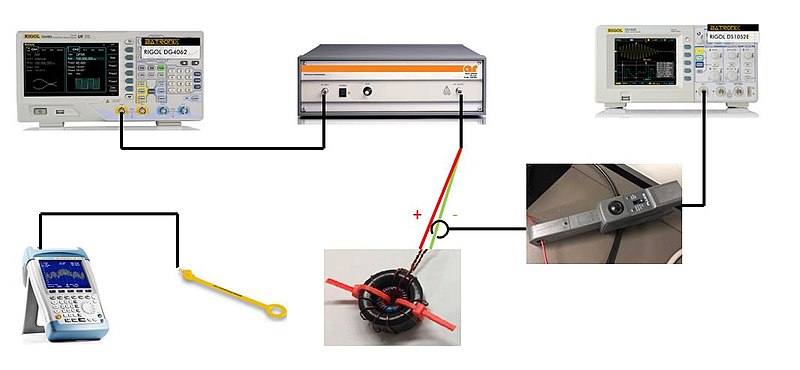

We need to conduct a current to the inductor and use a probe to measure the near field emission. First, a signal generator, serving as a voltage source, is connected to an amplifier. The output of the amplifier is then connected to the inductor under measurement. To monitor and control the current flowing through the inductor, a current clamp is clamped around the conducting wire. Next, an oscilloscope is connected to the current clamp to measure the current waveform. A probe is then used to measure the flux in the air. Another spectrum analyzer is connected to the probe to collect the data.

https://en.wikipedia.org/wiki/Choke_(electronics)

View More(Total0)Comment lists