What is the difference between wirewound inductors and laminated inductors?

Jul 22, 2019|

Jul 22, 2019| View:1050

View:1050

First, the introduction of winding inductance

Wirewound inductors are suitable for power supply circuits. This product is widely used in micro TVs, LCD TVs, video cameras, etc.

Winding inductance characteristics:

1. Suitable for power supply circuits.

2. Surface adhesion type.

3. Appearance and dimensions are EIA compliant and available in different sizes.

4. Good solderability and heat resistance, suitable for general welding and reflow.

Winding inductance:

The effect of the patch winding inductance. Basic functions: filtering, oscillation, delay, notch, etc.; image saying: "through DC, blocking AC" refinement: In the electronic circuit, the inductor coil acts on the AC finite current, and it can form a high-pass or a resistor or capacitor. Low-pass filter, phase shift circuit, resonant circuit, etc.; transformer can be AC-coupled, transformer, converter, and impedance-transformed. The effect of the patch winding inductance seems to be somewhat opposite. We have said that the capacitor is straight through, and the inductor is just the opposite. Its function is to block the direct, originally! The direction of the magnetic field generated when the DC current passes through the inductor is the same and does not change.

The alternating current changes positively and negatively, so the magnetic field also changes. Since the positive (negative) to negative (positive) is a short time, assuming a positive potential and rising, the magnetic field around the inductor is increasing. When it reaches the top, it is the peak. At this time, the potential begins to drop. Because of the presence of a magnetic field around it, the inductor converts the surrounding magnetic field into electrical energy, so that the electrical energy can be maintained for a period of time, and vice versa, thus preventing the passage of alternating current.

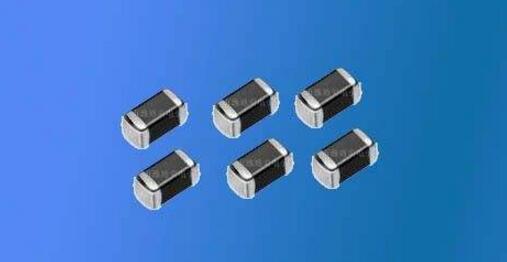

Second, the introduction of laminated inductors

Laminated inductors are also non-wound inductors. Laminated inductors are one type of inductor that classifies inductors by structure.

Laminated inductor characteristics:

1. Small size.

2. Closed circuit, no crosstalk, suitable for high density installation.

3. Non-directional, standardized automatic patch mounting profile.

4. Excellent weldability and solder resistance, suitable for flow soldering and reflow soldering.

Laminated inductor process:

1, ingredients

2, molding

3, cutting

4, glue

5, sintering

6, edging

7, sticky silver

8, burning silver

9, surface treatment terminal electrode

10, test

11, packaging

12, inspection

13, the factory

Laminated inductor applications:

At present, the product is widely used in notebook digital TV, digital video recorders, list machines, hard disk drives, personal computers and other general consumer and computer main products on the input and output lines of noise cancellation.

Third, what is the difference between winding inductance and laminated inductor

The wound-type inductor is the product of the miniaturization of the conventional wound inductor. The laminated inductor is fabricated by multi-layer printing technology and lamination production process, and the volume is smaller than that of the wound-type chip inductor.

Winding type inductor: It is characterized by a wide range of inductance (mH~H), high inductance precision, low loss (ie, large Q value), large allowable current, strong inheritance, simple manufacturing, low cost, etc. It is limited in terms of further miniaturization. The wound core type chip inductor of the ceramic core can maintain a stable inductance and a relatively high Q value at such a high frequency, and thus has a place in the high frequency circuit.

Laminated inductor: It has good magnetic shielding, high sintered density and good mechanical strength. Compared with the wound-type inductor, it has small size, is conducive to miniaturization of the circuit, and the magnetic circuit is closed and does not interfere with surrounding components. It is also not subject to interference from surrounding components, and is conducive to high-density mounting of components; laminated integrated structure, high reliability, good heat resistance, good solderability, and regular shape, suitable for automated surface mount production. The disadvantage is that the pass rate is low, the cost is high, the inductance is small, and the Q value is small.

In general, the laminated inductors are invisible, and the laminated inductors have good heat dissipation and smaller ESR values.

However, the withstand current is smaller than the winding inductance. The cost is lower than the wound inductor. The heat dissipation of the wound inductor is not as good as the laminated inductor, but the current resistance is large and the ESR value is higher.

View More(Total0)Comment lists